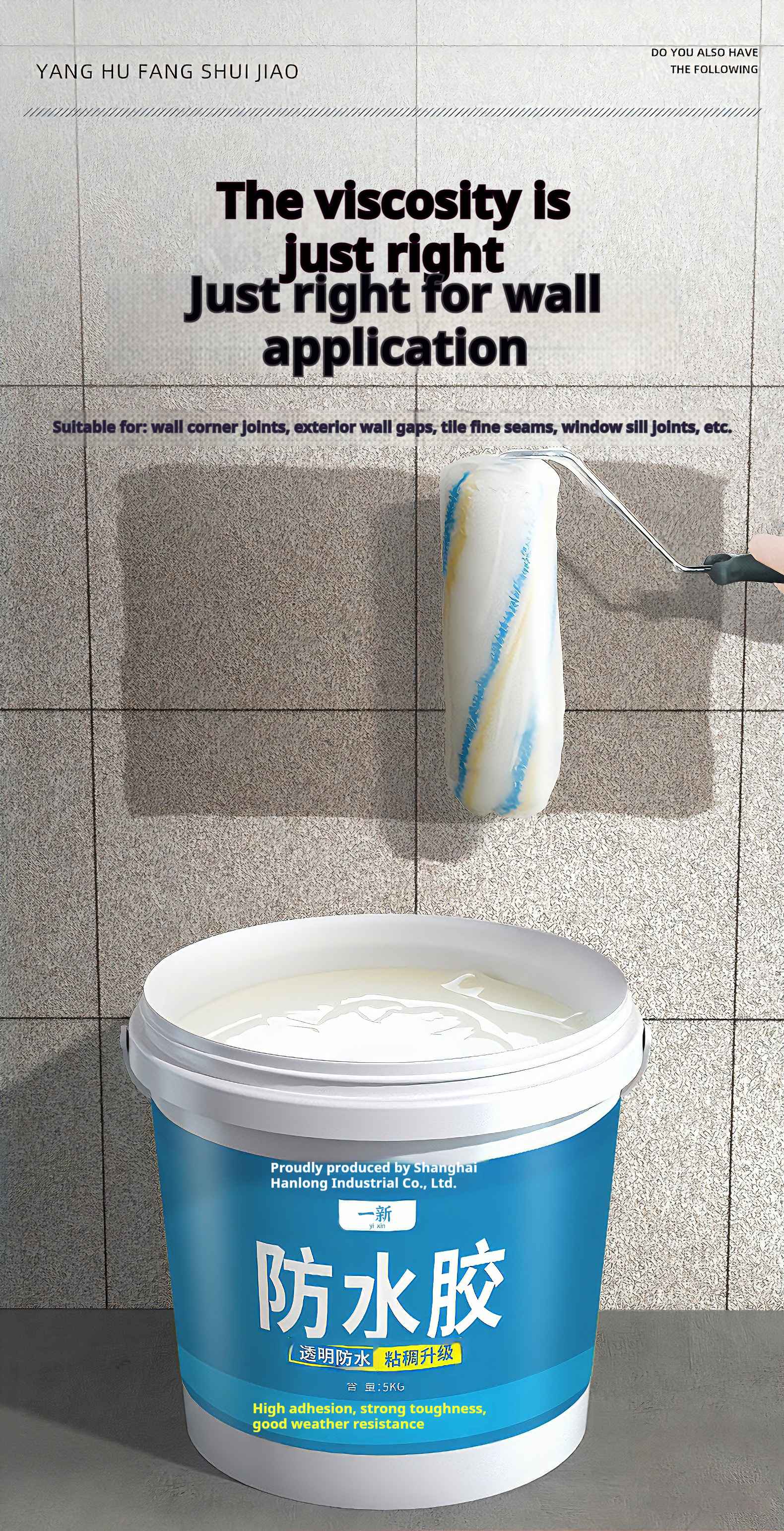

Exterior Wall Transparent Waterproof Sealant

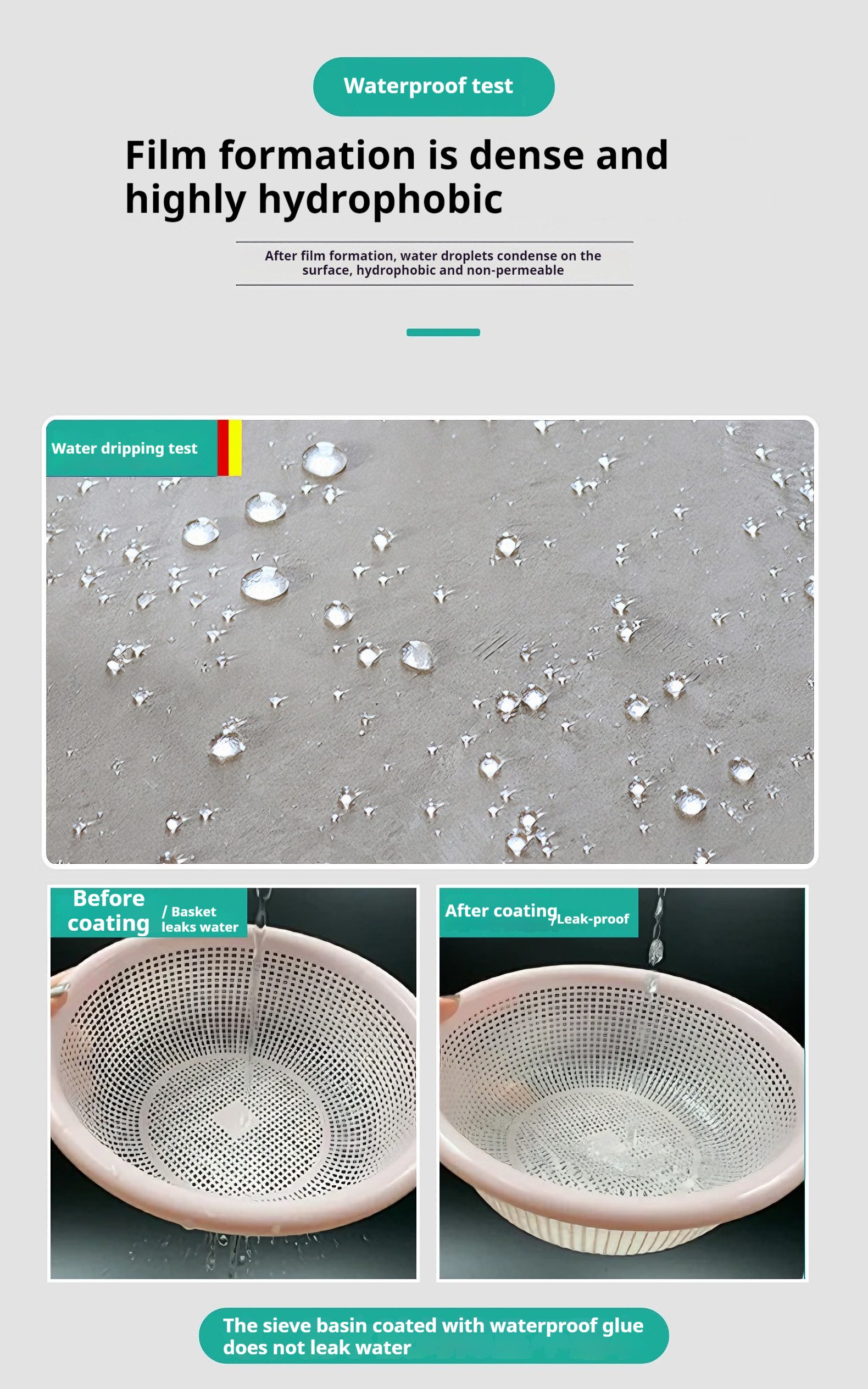

High Transparency & Invisible Aesthetics: After curing, the coating is completely transparent and does not alter the original color or texture of the wall—perfect for various finishes.

Outstanding Waterproofing & Long-Lasting Protection: Extremely low water absorption; excellent resistance to water intrusion; able to withstand rain for long periods without moisture penetration.

High Elasticity & Crack Resistance: The coating has excellent elongation; can cover micro-cracks (<0.5 mm), and expands/contracts with substrate without cracking.

Weather-Resistant & Durable Aging Performance: Added UV stabilizers; resistant to heat and cold, acid and alkali; suitable for harsh climates with long service life.

Good Breathability & Mold / Moisture Resistance: While waterproof, allows slight vapor transmission from inside substrate, preventing blistering or mold behind finishes.

Eco-Friendly & Easy Application: Water-based, non-toxic, odorless; meets environmental standards. Ready to use; can be applied by brush, roller or spray—saves time and effort.

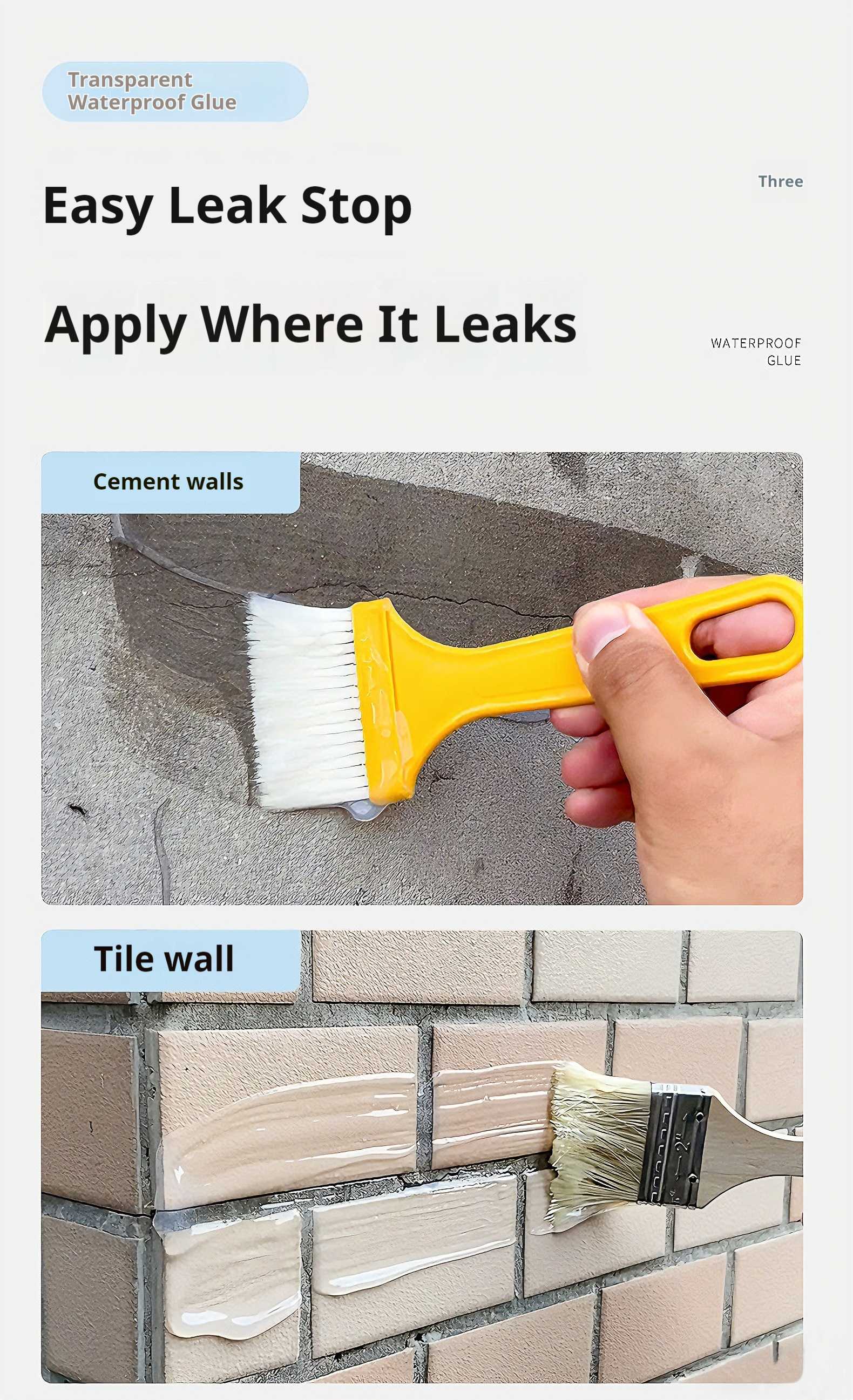

Wall Types: Cement-sand plaster surfaces, concrete, brick walls, natural stone curtain walls, decorative stone, real stone paints, tile grout joints, etc.

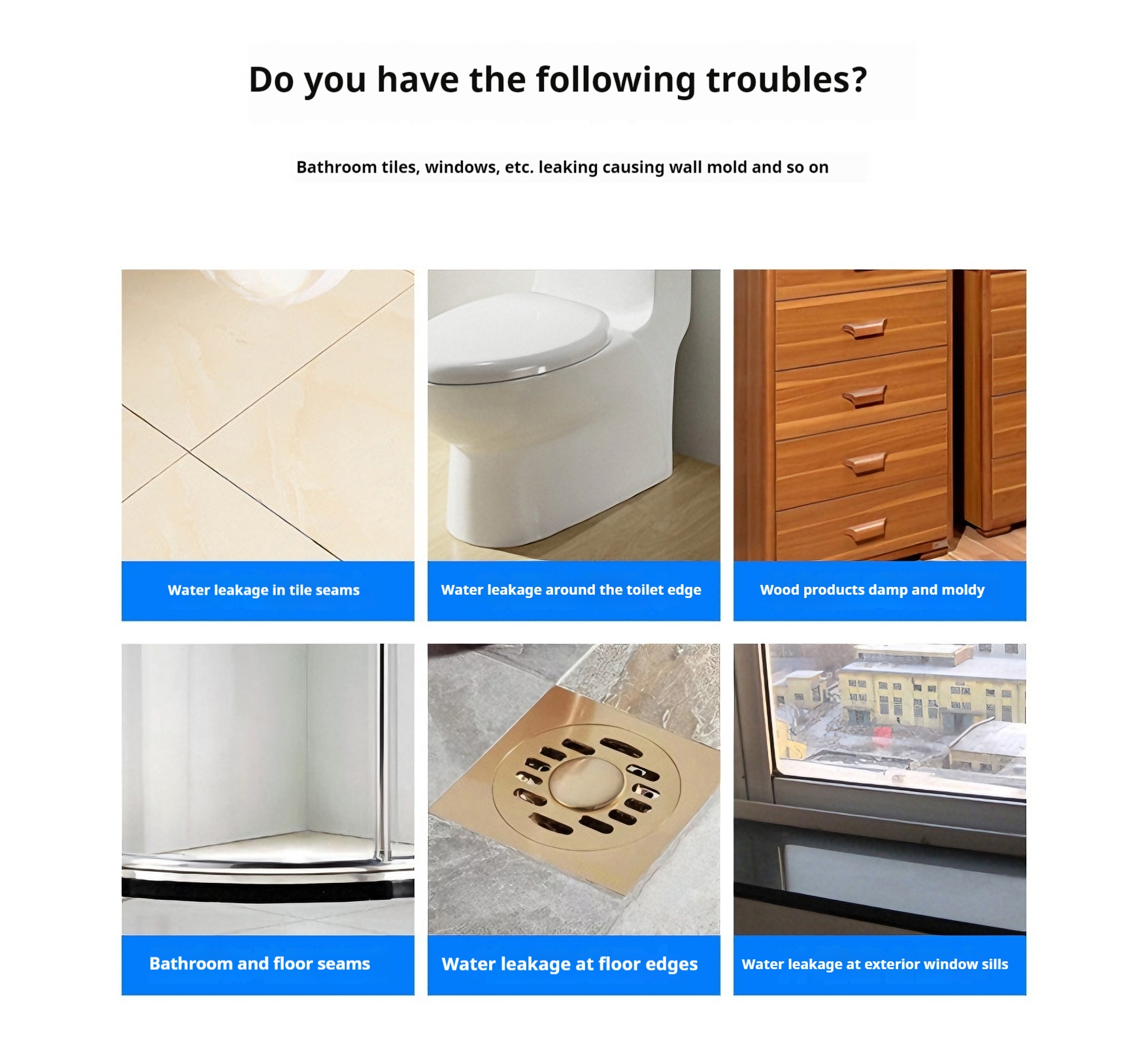

Use Cases:

• Waterproofing and seepage protection for exterior walls, balconies, terraces.

• Full external wall maintenance for villas, self-built houses, residential complexes.

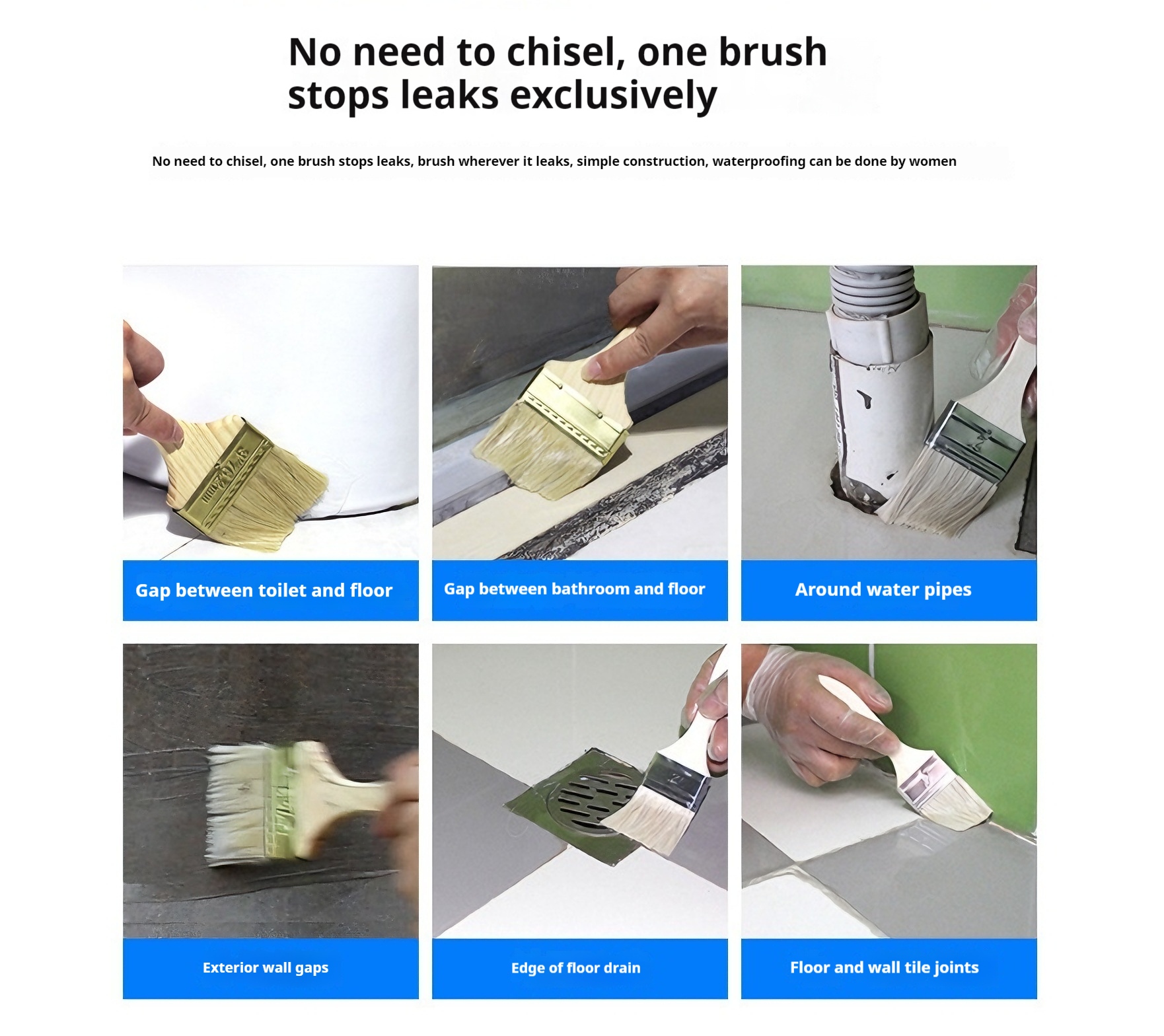

• Reinforcement at water-prone areas: around windows, AC units, baseboard edges.

• Renovation of old walls—no need to strip original finishes; direct application.

| Specification | Value |

|---|---|

| Product Size / Packaging | 20 kg |

| Appearance | Milky-white liquid; becomes transparent once cured |

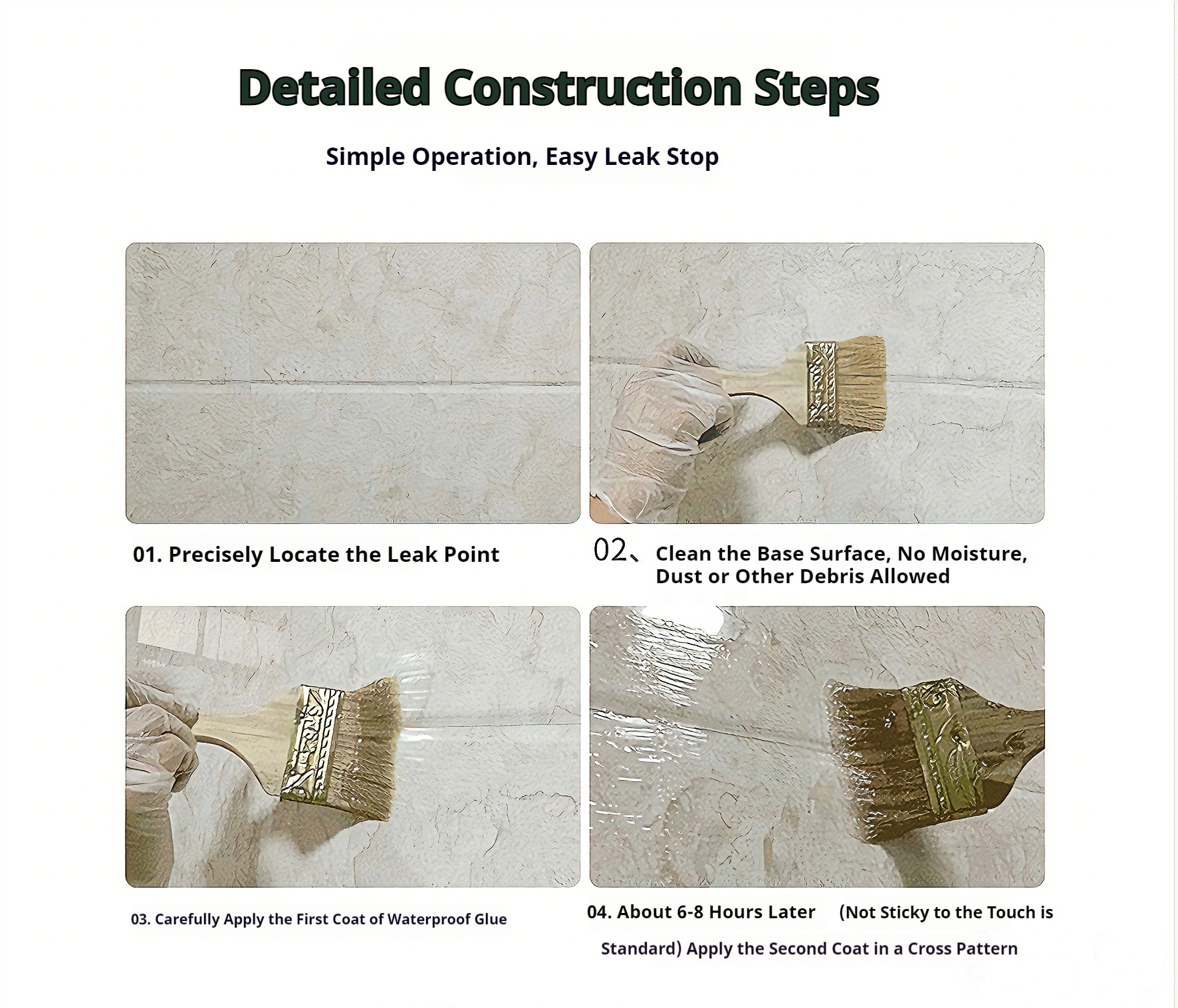

Surface Preparation

• Cleaning: Remove dust, oil, algae, loose particles; ensure substrate is sound, flat, clean.

• Repair: Fill visible cracks or holes > 0.5 mm with cement mortar or leak sealant; ensure smoothness.

• Drying: Substrate must be thoroughly dry.Application Method

• Stirring: Gentle mixing once opened; no dilution with water.

• Coating: Use roller, brush, or spray. Apply at least two coats; the directions should be perpendicular (first coat horizontal, second vertical).

• Drying between coats: First coat becomes surface-dry in about 2-4 hours (depending on weather) before applying the second.

• Coverage: Approximately 0.3-0.4 kg/m² per coat (actual use depends on substrate roughness).Curing / Maintenance

After completion, allow natural curing for 24-48 hours until film is fully hardened. Avoid exposure to rain or mechanical damage during this period.

Non-flammable and non-explosive; can be transported as general goods. During transport, protect from rain, direct sunlight, freezing, and package damage.

Store in a dry, cool place (5 °C - 35 °C), avoid exposure to sunlight or rain. Relative humidity ≥ 85% requires moisture protection. Under normal conditions of transport and storage, shelf life is usually 6 to 12 months.

Working environment: Avoid applying during rainy or foggy weather, or at temperatures below 5 °C or above 40 °C. If rain occurs within 6 hours after application, protective measures should be taken.

Personal protection: Wear gloves, safety goggles, etc. In case of contact with eyes, rinse with plenty of water immediately and seek medical advice.

English

English  简体中文

简体中文  Español

Español  Deutsch

Deutsch  Français

Français  Bahasa Indonesia

Bahasa Indonesia  Malaysia

Malaysia  Português

Português  Русский язык

Русский язык  بالعربية

بالعربية  Kiswahili

Kiswahili  বাংলা

বাংলা