Aerogel Coating

Product Description: This product is a novel functional coating composed of nano aerogel particles compounded with high-performance polymer emulsion. It leverages the extremely low thermal conductivity of aerogel to form a micro-porous insulation layer on the substrate surface, achieving highly efficient thermal insulation and combining the protective properties of traditional coatings with advanced energy-saving effects.

Precautions

| Content |

|---|

| Construction Temperature: Recommended environment temperature is 5–35℃; avoid construction during rain, snow, or strong winds. |

| Mixing Note: Avoid high-speed, long-duration mixing. Use a low-speed paddle mixer. |

| Thickness Control: Apply thin coats multiple times. Excessive single-layer thickness may cause cracking. |

| Tool Cleaning: Clean tools immediately with water after use. Once cured, removal is difficult. |

Product Features

| Content |

|---|

| High Thermal Insulation: Nano-porous structure provides an extremely low thermal conductivity (≤0.040 W/(m·K)), delivering excellent insulation performance. |

| Thin & Lightweight: A single-millimeter coating provides insulation equivalent to several centimeters of traditional materials, saving space. |

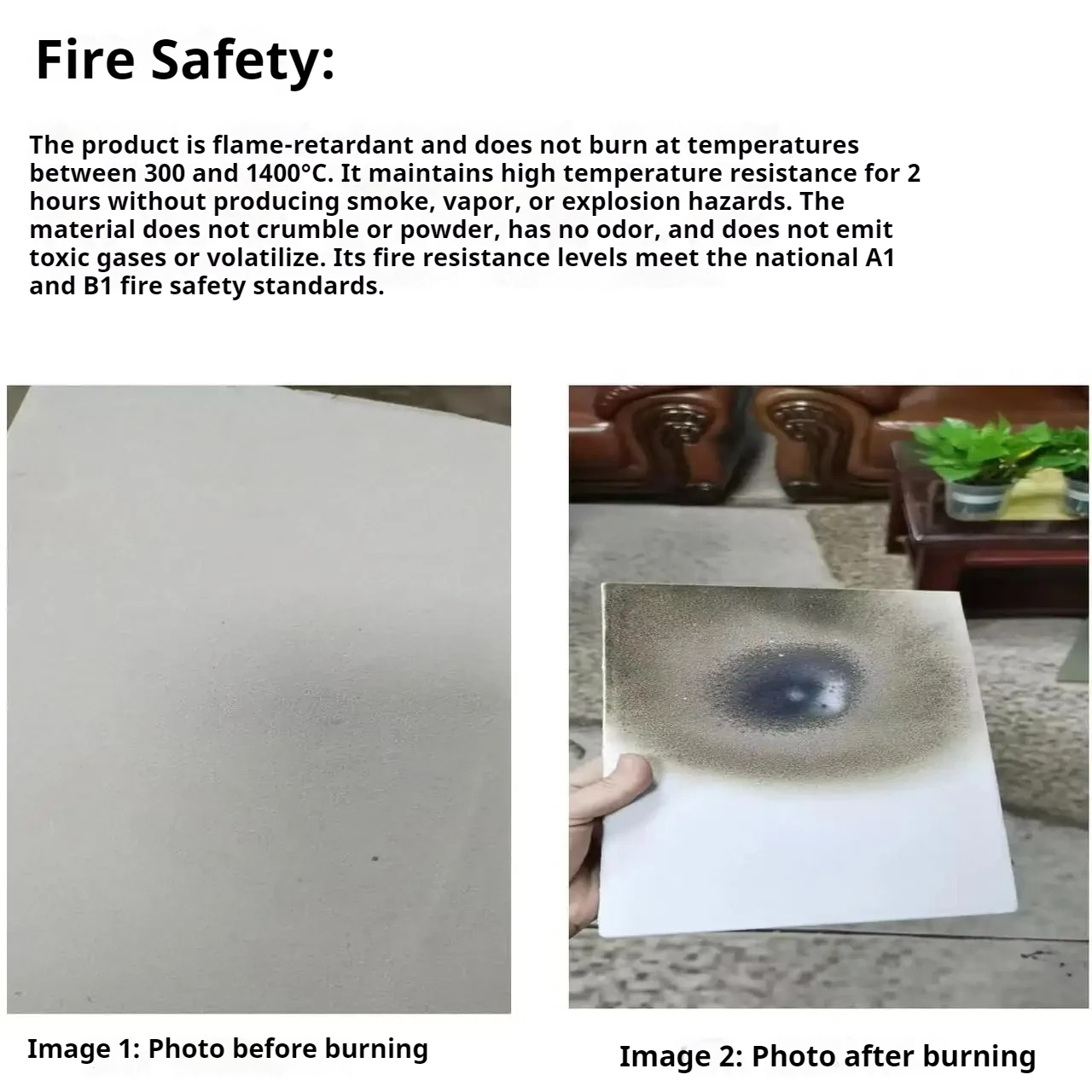

| Hydrophobic & Fire-Resistant: Excellent water repellency (water absorption <5%) and A2-class fire resistance. |

| Seamless Sealing: Continuous coating without joints, effectively eliminating thermal bridges and offering waterproof and moisture-proof protection. |

| Superior Durability: Outstanding weather resistance and aging resistance ensure long service life. |

Standard

| Content |

|---|

| Executed according to Q/GDHY 001-009 Standard |

Application Scope

| Content |

|---|

| Suitable for petrochemical tanks, building exterior walls, interior walls, factory roofs, and other areas requiring insulation and energy saving; especially ideal for irregular equipment, limited spaces, or areas where traditional insulation is difficult. |

Construction Process

| Content |

|---|

| Surface Preparation: The substrate should be flat, solid, and clean, free of oil and dust. Metal surfaces must be derusted. |

| Material Mixing: Stir slowly with a low-speed mixer after opening the bucket. Avoid high-speed mixing to prevent damage to the aerogel structure. |

| Layered Application: Apply 2-3 coats with a trowel or spray equipment. Each layer should be ≤1mm thick. |

| Interval Time: Apply the next layer after surface drying (about 2 hours). |

| Total Thickness Control: Final dry film thickness is usually 1-3mm, determined by thermal calculations. |

Product Specifications

| Item | Parameter |

|---|---|

| Packaging | 10kg |

| Appearance | White paste |

| Thermal Conductivity | ≤ 0.040 W/(m·K) |

Transportation & Storage

| Content |

|---|

| During transportation, avoid heavy pressure and severe impacts. |

| Store in a cool, dry environment at 5–35℃, protected from freezing. Shelf life is 6 months unopened. |

More related products

English

English  简体中文

简体中文  Español

Español  Deutsch

Deutsch  Français

Français  Bahasa Indonesia

Bahasa Indonesia  Malaysia

Malaysia  Português

Português  Русский язык

Русский язык  بالعربية

بالعربية  Kiswahili

Kiswahili  বাংলা

বাংলা