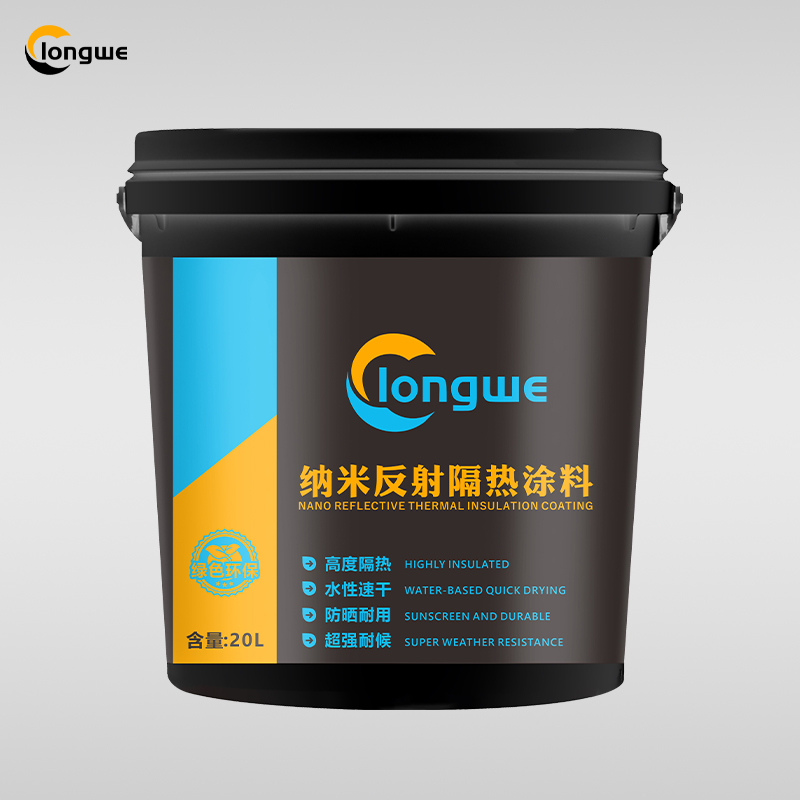

Nano Reflective Thermal Insulation Coating

Highly Efficient Radiative Cooling: Infrared emissivity ≥ 0.85, able to rapidly radiate internal heat of substrate to the environment via infrared wavelengths. In summer this can reduce surface temperature by 15-25 °C, internal temperature of industrial equipment by 8-15 °C. Significant energy savings.

Excellent Temperature Resistance: Operates stably in environments from -40 °C to 150 °C. Some high-temperature resistant grades can withstand short-term exposure above 200 °C without coating cracking, peeling, or degradation of insulation performance.

Strong Adhesion: Good adhesion to metals, concrete, glass, plastics, etc. Adhesion at ambient temperature ≥ 5 MPa. Once cured, the coating resists detachment due to vibration or impact.

Weather & Corrosion Resistance: UV aging resistance, acid-alkali erosion resistance, resistance to rain wash. Outdoor coating lifespan 5-10 years. Also isolates air and moisture from substrate, providing corrosion & rust prevention.

Easy, Thin & Lightweight Application: Dry film thickness only 50-100 µm. No complex substrate prep needed. Can be brush, roll, or spray applied. Good adaptability to irregular equipment or complex surfaces.

| Standard | Description |

|---|---|

| Implementation | GB/T 25261-2018 “Solar Heat Reflecting Insulation Coatings for Buildings”. The coating must meet radiation insulation performance as per standard (radiation emissivity ≥ 0.8). (全国标准信息公共服务平台) |

Construction Sector: Roofs (color-steel, concrete roofs), exterior walls, equipment room exteriors, glass roofs, large mall ceiling tops—especially in high-temperature regions for cooling.

Industrial Sector: Petrochemical storage tanks, reactors, power plant cooling tower exteriors, high-temperature equipment in metallurgy.

Transportation Sector: Container exteriors, truck bodies, construction machinery equipment shells, ship decks and exterior of cabins.

Special Scenarios: Solar panel backboards (aiding heat dissipation), large outdoor transformer housings, outside walls of telecom base stations.

| Specification | Detail |

|---|---|

| Weight / Packaging | 20 kg |

| Color | Standard white |

Transportation: Stack no more than five buckets high. Protect from rain, intense sunlight, exposure during transit. Transport temperature controlled between 5-35 °C.

Storage: Store in cool, dry, well-ventilated warehouse. Unopened product shelf life: 18 months. Once opened, use same day. Remaining coating must be sealed tightly to prevent skinning.

Substrate Preparation: Surface must be level, clean, free of oil, rust, dust, loose coatings, and debris. For metal, sand/rust remove to Sa2.5 or St3 standard. For concrete, fill cracks/holes with repair mortar, let dry then sand smooth. Suggested primer (anti-rust) for metal at 20-30 µm dry film, dry 6-8 hours, before applying the reflective insulating top coat to improve adhesion and corrosion resistance.

Coating Preparation: Stir paint sufficiently for 5-10 minutes prior to application to ensure homogeneous dispersion, no settling or lumping. May thin with clean water (≤ 5%) if needed. Let the stirred coating rest for 10 minutes to allow bubbles to subside; avoid pinholes later.

Application Method: Prefer spraying (nozzle 1.2-1.8 mm, pressure 0.4-0.6 MPa). Brush or roll also acceptable. Maintain spray gun perpendicular to substrate surface, distance 30-50 cm, move at uniform speed, avoid missed spots or runs. Apply two coats; after first coat dried, apply second coat in direction perpendicular to first. Total dry film thickness should be 50-100 µm.

Curing & Drying: Surface dry in 2-4 hours at ambient temperature; thoroughly dry in 24 hours; full cure in 72 hours. During curing avoid rain, foot traffic, impact. If applying subsequent layers, wait until full cure.

Environmental Conditions: Avoid application on rainy days, strong wind (>6 m/s), temperatures below 5 °C or humidity above 85%.

Safety Measures: Wear respiratory mask, protective clothing. Prevent inhalation or contact with clothing. If coating contacts skin or eyes, rinse immediately.

Coating Protection: Avoid stepping on or stacking objects before cure. If damage, repair immediately; peeling or bubbling requires scraping off and recoating fully.

English

English  简体中文

简体中文  Español

Español  Deutsch

Deutsch  Français

Français  Bahasa Indonesia

Bahasa Indonesia  Malaysia

Malaysia  Português

Português  Русский язык

Русский язык  بالعربية

بالعربية  Kiswahili

Kiswahili  বাংলা

বাংলা