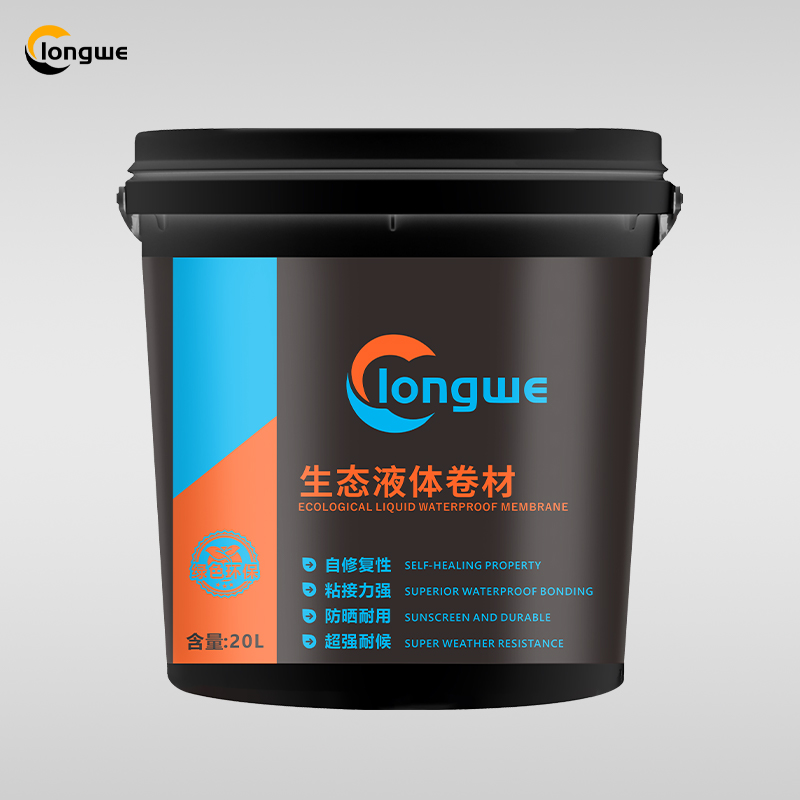

Liquid Waterproof Membrane

This product is a water-based, single-component waterproof coating made from polymer-modified emulsified asphalt and various additives. It combines the excellent waterproof performance of traditional membranes with the convenience of coating application. After application, it forms a highly elastic, seamless rubber-asphalt waterproof film, known as the “breathable liquid membrane.”

Excellent waterproofing: forms a dense, seamless layer that completely prevents leaks.

High elasticity & crack resistance: large elongation, can effectively cover fine cracks in substrate; adapts to temperature differences and structural movement.

Strong adhesion: bonds firmly to cement-based substrates, asphalt membranes, metal panels etc.

Good weather resistance: resists aging; stable performance under both high and low temperatures.

Easy application: cold application (no heating needed); spread or roll; safe and environmentally friendly.

Complies with JC/T 408-2005 “Emulsified Asphalt Waterproof Coating”, which covers classification, requirements, test methods, inspection, packaging, marking, transportation and storage for water-emulsion asphalt waterproof coatings.

| Step | Details |

|---|---|

| Substrate Preparation | Substrate should be level, solid, clean; free of visible water or oil. Cracks or defects must be repaired in advance. |

| Detailing / Nodes | Apply reinforcing layer at nodes (corners, pipe roots etc.); mesh reinforcement is recommended. |

| Coating Application | Stir well. Use trowel or roller to apply in 2-3 coats. Between coats, wait until the previous coat is surface dry (approx. 4-6 hours at normal temperature). |

| Usage / Thickness | Final dry film thickness should be ≥ 1.5 mm. Theoretical usage roughly 2.5-3.0 kg/m². |

| Specification | Value |

|---|---|

| Packaging | 20 kg |

| Appearance / Color | Black / Dark Grey viscous liquid |

During transport, protect against strong sunlight, rain, freezing, and mechanical damage.

Store in ventilated, dry, shaded area at 5-35 °C; avoid high temperature exposure.

Unopened product shelf life: 12 months under proper storage conditions.

Working environment: apply only when temperature is above 5 °C; avoid application during rain or strong winds.

Drying time: fully cured film takes about 24-48 hours; avoid walking on or doing subsequent work until fully cured.

Protection & health: ensure good ventilation at site; wear gloves / eye protection; if product gets into eyes, rinse with plenty of water & seek medical advice.

English

English  简体中文

简体中文  Español

Español  Deutsch

Deutsch  Français

Français  Bahasa Indonesia

Bahasa Indonesia  Malaysia

Malaysia  Português

Português  Русский язык

Русский язык  بالعربية

بالعربية  Kiswahili

Kiswahili  বাংলা

বাংলা